Ladder Accidents - (855) 627-6273

Ladder accidents are a common occurrence that are often the result of inadequately designed and manufactured ladders. Life-changing injuries can result from these defective products. Ladder accidents are often classified as falls from ladders. While some people presumably fall from ladders because of losing their balance, many ladder accidents are the result of defective ladders. When a leg or legs of a ladder fail due to inadequate design, manufacturing defects, or material defects, the ladder collapses under the weight of the user, sending the ladder user falling to the ground. Ladder instability results in the racking of stepladders, where the rear section of the ladder is shifted relative to the front section of the ladder. This can occur due to climbing the ladder, or from normal use. Once racked, the stepladder can easily tip over. MASE has decades of experience analyzing defective ladders and reconstructing ladder accidents. Stepladders are often designed to be constructed out of a minimum amount of material. This is to meet pricing requirements of large retail chains and to be competitive with all of the other stepladder manufacturers. These ladders are then usually manufactured in foreign countries, some of which may not have adequate quality control. These sad precedents have led to a multitude of cheaply-made ladders that are extremely unsafe. Ladders place the user in a position to be severely injured, paralyzed, or killed. A fall from a standard stepladder can result in debilitating injuries or worse. This necessitates ladders to be as safe as possible, to be completely stable.

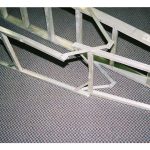

Unstable stepladders exhibit "racking", a state that occurs when the rear legs of a stepladder become misaligned with the front legs of the ladder. This creates an unstable ladder with three points of contact with the ground, because the fourth leg is not touching the ground due to the sideways displacement of the rear legs. Racking can occur due to a variety of normal-use scenarios including climbing the ladder, descending the ladder, working from the ladder, repositioning the ladder, etc. Racked ladders are extremely unstable and can cause the ladder to topple over, sending the user crashing to the ground with no warning. Solutions to the problem of racking have been available for many years. MASE has built and tested some of these solutions, as well as designed, built, and tested design solutions of our own. Other problems that can result in stepladder failures include defective manufacturing, inadequately designed support structure, and material defects.

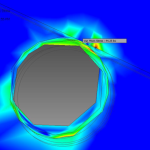

Extension ladder users can also experience falls from the ladder due to defective ladder components. The most common cause of extension ladder accidents that are the result of a defective ladder is false-lock. False-lock occurs when the locking mechanism that holds the different parts of an extension ladder partially engages the two sections. When the ladder experiences changing forces from the user ascending or descending the ladder, this partial-engagement can and does disengage, resulting in the collapsing of the two ladder sections. MASE can investigate extension ladder accidents and determine if it was due to a false-lock, or other contributing factors such as material defects or unstable design.

Articulated ladder accidents occur when hinges fail, usually the mechanism that locks the ladder hinge fails, allowing the hinge to rotate with the user on the ladder. This results in the user falling from the ladder. Hinge failure is a serious hazard of poorly designed articulated ladders.

Attic ladder accidents occur when the attic ladder experiences a structural failure. A big problem with traditional style attic ladders is that the length of the ladder is normally custom fit in each home. Attic ladder safety and stability is highly dependant on how accurately the ladder is cut to length. An attic ladder that is too short or too long will place increased stresses on the ladder connections.

From a hierarchy of design perspective that calls for all hazards of a design to be eliminated and all other hazards to be guarded, ladders should also provide safeguards to protect the user from the hazard of falling from an elevated height. This would involve fall arrest systems or containment systems that would prevent the user from falling.

MASE has over 25 years of experience investigating ladder and chair failures, finding the cause of the failure, utilizing scientific methodology, and testifying about our findings. Call us today at (855) 627-6273 or email us at info@mase.pro to your client's ladder or chair accident.

Chair Accidents.

Chair accidents can involve a variety of different causes. Even though the height of a chair is small, a person using a chair is in a compromised position, where the body is not positioned to safely absorb the shock forces involved in a fall.

Chair Tipping

A common chair accident involves the tipping of a chair. A tipping chair can be the result of a design defect or a misuse of the chair. Virtually any chair can be tipped if enough force is applied to the chair. Engineering experts can determine if a chair design is not stable enough to protect the chair occupant in all foreseeable positions of the chair using simple engineering principles and equations. ANSI/BIFMA standards have tests that establish a minimum stability requirement for chairs—exemplar chairs can be tested to this standard to see if it meets this minimum criteria. An accident involving a tipped over chair could be the result of a design flaw, that product testing can determine. We are able to typically track down an exemplar chair like the one involved in an accident, and run industry standard tests as well as non-destructive material testing.

Chair tipping may be a design flaw

Structural Support Failure

Many chair accidents involve a failure of a structural member of the chair that causes the chair to collapse, injuring the chair occupant. These types of structural failures are often a design flaw. Sometimes the chair legs are not sized properly, or not braced adequately. The material specified for the chair structure may not be the same material that the chair is constructed out of. Last minute design changes can be made that are not checked, or the production facility may use a material different than what is specified by the designer. The material may also not meet specifications due to a defect in the material. Some failures involve the leg of a chair that buckles causing the chair to collapse. These types of failures are often due to design defects where the chair is simply not designed to adequately support the chair occupant. This can occur when an engineer designs a chair for the weight of the person, without taking into account dynamic forces.

Dynamic forces occur whenever motion is involved—for instance, often when people sit in a chair they drop down into it as opposed to easing into it very slowly. This natural tendency to drop into a chair because of the padding places high forces on a chair that it must be designed to withstand. Dynamic forces can easily increase the stress on a chair by 4 to 6 times. Folding chairs including theater and stadium seating have moving components and bracing that can be more susceptible to failure than non-folding chairs. The strength of a standard folding chair depends on the bracing mechanism between the folding members. If this is not designed properly, deformation or failure of the brace can occur, resulting in chair failure.

Deformed folding chair brace

Seat Back Failure

Failure of a chair seatback can result in serious injuries. These failures are often due to the seatback being inadequately fastened to the rest of the chair structure.

Connection Failure

Failure of structural chair connections can cause chair collapse. Weld defects in welds combining metal chair components can cause chair failure. This is a simple defect to identify after a chair collapse. Inadequate material penetration is a common cause of weld failure. Bolts and rivets can also fail due to inadequate sizing of these components, or due to a design defect that puts excessive stress on the connection.

Fatigue Failures

Many chairs have various spring mechanisms incorporated into their design. This may involve an actual spring, or the spring effect may be obtained by yielding of the material—some chair backs are designed to bend when a person leans into the chair. This can be accomplished by using a material with enough elasticity to yield under load, but enough strength to prevent failure. If this is not designed correctly, fatigue failures can occur. Fatigue failures occur from repeated loading to an object., and often involve small cracks that grow until failure occurs.

Pinch Points

Certain chairs that fold or recline have pinch points where hands or other body parts can get injured or amputated. Children are usually the victims of these types of accidents. Folding recliners may have pinch points that can harm a child. A particular CPSC recall involves a reclining chair with a gap between the seat cushion and the foot rest that was too big, allowing infants and small children to lean against the foot rest, fit their head in this space, and become strangled when the foot rest closed. High chairs can fail and collapse, not only injuring the child in the seat, but nearby children may get injured by the collapsing legs of the high chair.

Weathering/Aging

Outdoor seating that is subjected to sunlight may be weakened by constant exposure to ultraviolet radiation. Plastics and fiberglass are particularly susceptible to sunlight. Prolonged exposure to sunlight with these materials will weaken the strength of these materials, which can result in failure.

What We Can Do For You:

- Provide mechanical engineering expertise for your product liability case

- Help you decide on whether to take a case—we’ll give you a free, no obligation case assessment just call us at (855) 627-6273

- Perform detailed and thorough engineering analysis of products involved in accidents

- Communicate technical information effectively

- Design solutions to product hazards that are left unguarded