Defects in Materials and Design Used in Stepladders and Other Structures / Strength of Wood

Written by Dr. L.D. Ryan, Ph.D. First published September 2003.

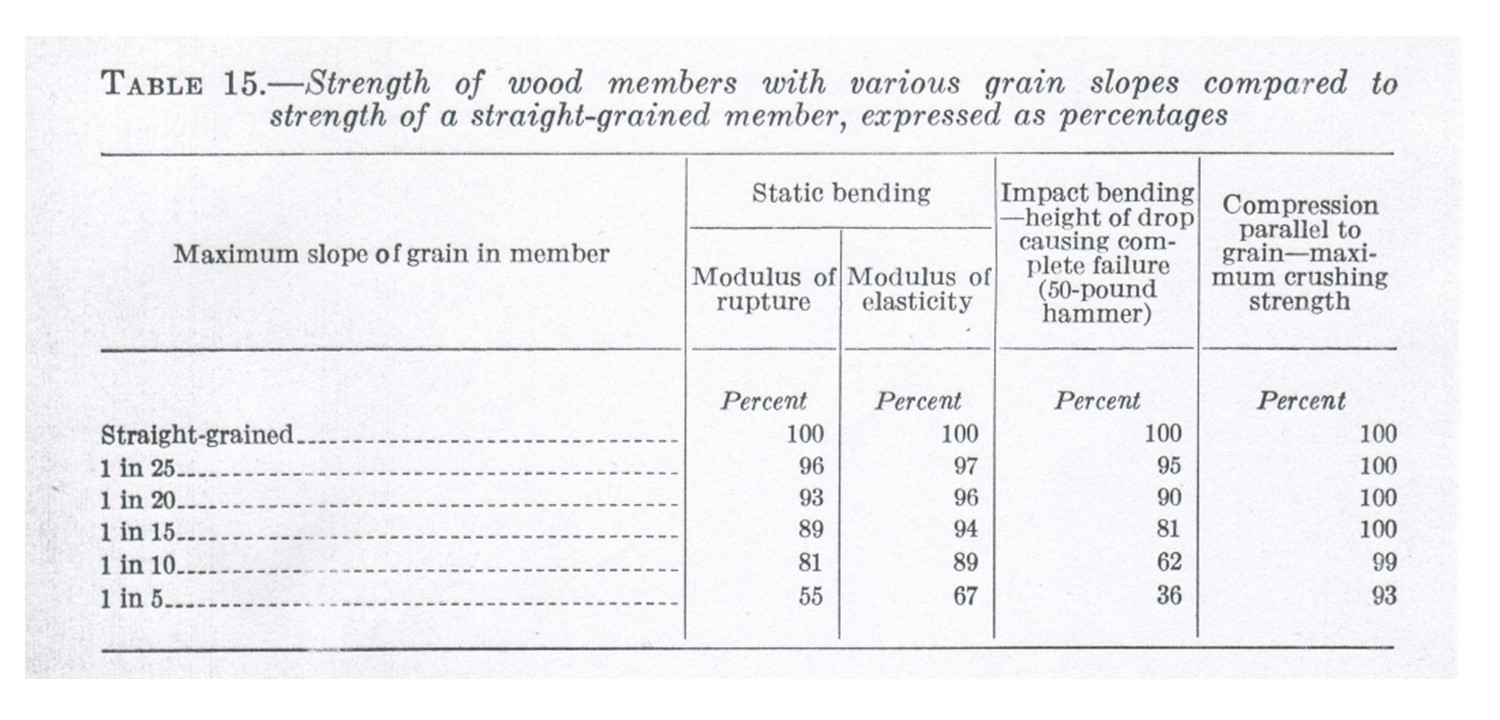

In wood stepladders check the wood grain at the break. The grain must be parallel to the longitudinal axis. The wood strength is reduced significantly if the grain is not parallel. Straight grained wood gives 100% strength, but if the grain is sloped, then the strength is reduced. In Figure below, the wood is much weaker due to the slope of the wood grain. The strength is approximately cut in half. This information comes from Table 15 out of Wood Handbook (published in 1955 and 1999, Wood Handbook, Handbook No. 72, 1955, by the U.S. Department of Agriculture, Page 97) that predicts the weakening effect of wood grain that is sloped.

For aluminum stepladders look for members that break-off but are not bent. Aluminum members should bend before they break. Shown is an obvious material defect in a stepladder.

Another common failure is the lower stepladder leg buckles inward. This is the area of high stress and happens frequently in certain ladders..